services

Home / Services

WE PROVIDE ADVANCED ENGINEERING ANALYSIS AND MULTIDISCIPLINARY DESIGN SOLUTIONS

PIPELINES

Oil and Gas Pipelines, SAGD pipelines, tailing pipelines, waster water pipelines

- Front End Engineering

- Detailed Engineering

- Stress Analysis

- Terrain Mapping

- Geotechnical Engineering

- HDD Design

FACILITIES

Upstream facilities, process plants, refineries, waste water treatment

- Front End Engineering

- Detailed Engineering

- Management of Change (MOC)

PIPELINE AND EQUIPMENT INTEGRITY

Pipelines, upstream facilities, process plants, refineries, waste water treatment

- Remaining Life Calculations

- API 579 Level I, II and III Evaluations

- Safe Operating Windows

- Change in Service Assessment

- ILI Data Evaluations

REGULATORY & COMPLIANCE

Independent design reviews, specification reviews, code compliance reviews, regulatory services

- Facility and Pipelines

- Pressure Vessels

- Custom Fittings

- Piping Registrations

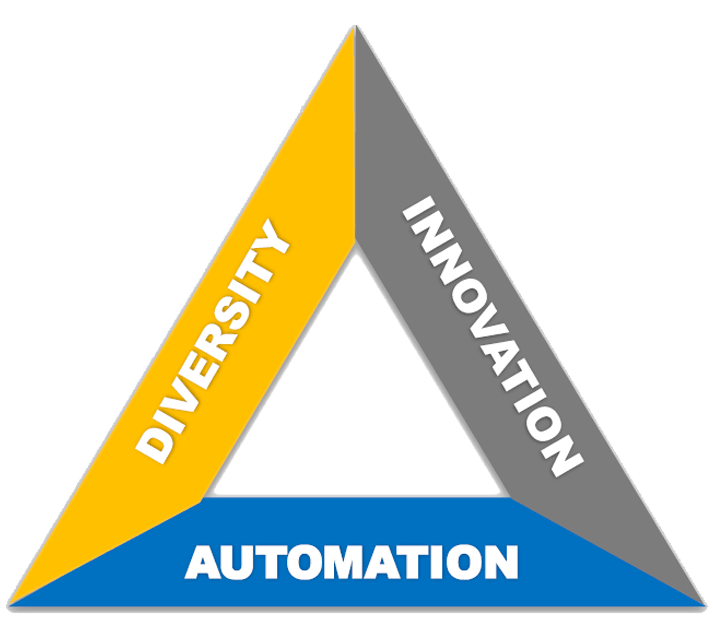

Our Differentiators Promise Sustainable Value

WE incubate diversity

Broad industry experience that ensures premium solutions with an in-depth understanding of risks

23

Professional

Engineers

17

Contract

Partners

+350

Years of Combined Experience

WE harvest innovation

Active R&D and collaborative research to promote new technologies and processes

14

Publications

10

Collaborative Research Projects

6

National Research Grant

5

University Collaboration

WE drive efficiency

Eliminating redundancies and repetitive tasks, while enhancing reliability

8

In-house tools

60+

In-house specifications